SEL-351S Instruction Manual⁚ A Comprehensive Guide

The SEL-351S instruction manual serves as a complete resource for effectively installing, configuring, and operating the SEL-351S relay․ This guide offers critical information on settings, protection functions, and troubleshooting tips for optimal relay performance and power system management․

Overview of the SEL-351S Relay

The SEL-351S Protection and Breaker Control Relay stands out as a comprehensive solution in power system protection․ Designed by Schweitzer Engineering Laboratories (SEL), this relay integrates protection, monitoring, control, and fault locating features into a single device․ Its capabilities extend to wide-area system stability awareness, facilitated by IEEE C37․118 synchrophasors, and streamlined communication through built-in Ethernet․ The SEL-351S proves ideal for directional overcurrent applications, offering advanced functionality for utilities and industries;

This relay caters to various SEL-351S models equipped with screw terminal blocks, introduced in 2009, ensuring compatibility and ease of integration․ Whether it involves medium voltage or critical power projects, the SEL-351S excels in transforming conceptual designs into practical, effective solutions․ Its versatility, coupled with SEL’s commitment to quality, makes it a reliable asset for enhancing power system safety, reliability, and economic efficiency worldwide․ Proper utilization, as detailed in this comprehensive manual, unlocks the relay’s full potential for optimized performance․

Key Features and Benefits

The SEL-351S relay offers a suite of key features that translate into significant benefits for power system protection and control․ Its exceptional package integrates protection, monitoring, and control functionalities․ The inclusion of IEEE C37․118 synchrophasors enhances wide-area system stability awareness, enabling proactive responses to grid disturbances․ Built-in Ethernet simplifies communication, facilitating seamless integration with modern network infrastructure․ The relay’s fault locating capabilities further expedite maintenance and minimize downtime․

Users benefit from the relay’s versatility and adaptability to various applications, including directional overcurrent protection․ Its configurable settings allow customization to specific system requirements․ With advanced control logic, the SEL-351S enhances system reliability and reduces operational costs․ Its capacity to supervise manual or automatic reclosing, coupled with synchronism check and voltage condition logic, ensures safe and efficient restoration of power․ Ultimately, the SEL-351S empowers users to optimize power system performance with confidence․

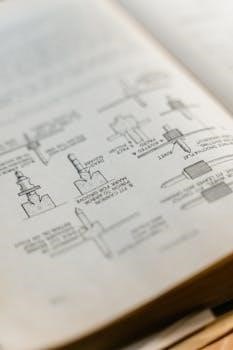

Installation Instructions

Proper installation of the SEL-351S relay is crucial for ensuring its reliable operation and optimal performance within the power system․ These instructions cover the procedures for safely and effectively installing the relay․ Before starting the installation, carefully inspect the relay for any signs of damage incurred during shipping․ Ensure that the installation environment meets the specified temperature, humidity, and vibration limits to prevent premature failure or malfunction․

Mount the SEL-351S securely in a suitable enclosure or panel, providing adequate space for ventilation and access to connections․ Wiring connections must adhere to applicable safety standards and regulations․ Use appropriately sized conductors and properly torque all terminal connections․ Verify all wiring connections for accuracy before energizing the relay․ Grounding is essential for safety and to minimize electrical noise․ After completing the installation, perform a thorough visual inspection and electrical testing to confirm proper wiring and functionality before placing the relay into service․ These steps will facilitate a secure and reliable integration of the SEL-351S into the power system․

Configuration Settings

Configuring the SEL-351S relay involves setting parameters to tailor its protection and control functions to the specific requirements of the protected power system․ These settings define how the relay responds to various system conditions, such as overcurrents, overvoltages, and faults․ To ensure optimal performance, it is essential to understand the purpose and impact of each setting before making adjustments․ The SEL-351S relay offers a wide range of configurable settings accessible via its communication ports․ These settings are organized into functional groups, such as protection elements, control logic, and communication parameters․

Use the appropriate software tools, such as SEL AcSELerator QuickSet, to modify the relay settings․ Before making changes, document the original settings to allow for easy restoration if needed․ Verify the accuracy of entered settings and thoroughly test the relay’s response to simulated fault conditions to confirm proper operation․ Regular review and adjustment of configuration settings are crucial to maintain optimal protection as the power system evolves․

Operating Instructions

Operating the SEL-351S relay involves understanding its controls, indicators, and communication interfaces․ The relay’s front panel provides visual indications of its status, including alarms, trips, and communication activity․ Use the relay’s pushbuttons to manually control breakers, reset alarms, and access settings․ The SEL-351S relay can be operated remotely through its communication ports using protocols like Modbus or DNP3․ Remote operation enables control of breakers, monitoring of relay status, and retrieval of event logs․

Properly train personnel on the relay’s operating procedures, including breaker control, alarm handling, and data retrieval․ Regularly monitor the relay’s status and alarms to promptly address any abnormal conditions․ Keep a log of all manual operations and relay events to facilitate troubleshooting and analysis․ By following these operating instructions, users can maximize the benefits of the SEL-351S relay and ensure the reliable protection of their power systems․

Protection Functions

The SEL-351S relay incorporates a comprehensive suite of protection functions, including overcurrent, overvoltage, undervoltage, frequency, and directional elements․ These protection functions safeguard power systems from various fault conditions, such as short circuits, overloads, and voltage sags․ The relay’s overcurrent protection detects and responds to excessive current flow, tripping breakers to isolate faulted sections․ Overvoltage and undervoltage protection protects equipment from abnormal voltage levels․

Frequency protection detects deviations from the nominal system frequency, initiating corrective actions to maintain system stability․ Directional elements differentiate between faults upstream and downstream from the relay, allowing for selective tripping․ The SEL-351S relay offers flexible settings for each protection function, enabling users to customize the relay’s response to specific system requirements․ Properly configuring these protection functions ensures the reliable and effective protection of power system assets․

Monitoring and Control Features

The SEL-351S relay provides extensive monitoring and control capabilities, enhancing power system management․ It monitors various parameters, including voltage, current, frequency, power, and energy, offering real-time insights into system performance․ The relay also features control functions for breakers, reclosers, and other equipment, enabling remote operation and automation․

Operators can use the relay to open or close breakers, adjust transformer taps, and control capacitor banks․ The SEL-351S supports multiple communication protocols, allowing integration with SCADA systems for centralized monitoring and control․ It also includes alarming and event recording features, providing valuable information for fault analysis and system diagnostics․ The monitoring and control features of the SEL-351S relay empower users to optimize power system operation, improve reliability, and reduce downtime through informed decision-making and automated responses․

Fault Location Capabilities

The SEL-351S relay boasts advanced fault location capabilities, enabling rapid identification and isolation of faults within the power system․ By analyzing voltage and current waveforms, the relay accurately estimates the distance to the fault, expediting repair efforts and minimizing downtime․ The SEL-351S supports various fault location algorithms, including impedance-based methods and traveling wave techniques, ensuring accurate results in diverse network configurations․

The relay provides detailed fault reports, including fault type, location, and time of occurrence, facilitating comprehensive post-fault analysis․ These reports can be accessed locally or remotely, allowing engineers to quickly assess the situation and dispatch maintenance crews to the precise location․ The fault location capabilities of the SEL-351S relay significantly improve system reliability by enabling swift and targeted responses to faults․

Communication Protocols and Ethernet Connectivity

The SEL-351S relay offers versatile communication capabilities through various protocols and Ethernet connectivity, ensuring seamless integration with existing systems․ Supporting industry-standard protocols like Modbus, DNP3, and IEC 61850, the relay facilitates interoperability with SCADA systems, human-machine interfaces (HMIs), and other intelligent electronic devices (IEDs)․ Built-in Ethernet ports enable high-speed communication over TCP/IP networks, enhancing data transfer rates and network reliability․

The SEL-351S relay also supports secure communication protocols, such as IEC 62351, ensuring data integrity and preventing unauthorized access․ This enhanced security is crucial for protecting critical infrastructure from cyber threats․ With its flexible communication options and robust security features, the SEL-351S relay provides reliable and secure data exchange, facilitating effective monitoring and control of the power system․

Manual Change Information and Revisions

This section details the history of changes and revisions made to the SEL-351S instruction manual․ Each update reflects improvements, clarifications, or additions to the information provided, ensuring users have access to the most accurate and up-to-date guidance․ The date code located at the bottom of each page indicates when the content was created or revised․

Users should review this section regularly to stay informed of any modifications that may impact installation, configuration, or operation procedures․ Significant changes are highlighted to draw attention to critical updates․ Consulting the latest revision of the manual is essential for ensuring proper use of the SEL-351S relay and maximizing its performance․ This commitment to continuous improvement ensures the manual remains a reliable resource for all users․

Troubleshooting and Maintenance

This section provides comprehensive guidance on troubleshooting common issues encountered with the SEL-351S relay and outlines recommended maintenance procedures to ensure optimal performance and longevity․ It includes step-by-step instructions for diagnosing problems, interpreting fault codes, and implementing corrective actions․

Regular maintenance is crucial for preventing failures and maintaining the relay’s reliability․ This section details recommended inspection intervals, cleaning procedures, and testing methods․ It also provides information on identifying potential issues before they escalate into major problems․ Additionally, this part discusses safety precautions to take when working with the SEL-351S relay, and provides a list of common problems that can occur with the relay, and what can be done to fix them․